spWall TiltUp Wall Panels

Tilt-Up construction combines the strength and durability of reinforced concrete with the precision and efficiency of the Design-Build methodology. This one-two punch delivers new buildings quickly and economically, which might explain why more than 650 million square feet of Tilt-Up buildings go up every year.

The Entire Process Of Concrete Tilt Wall Construction Archicad Bim Center Hire Best Home

The patented LiteForm TILT® system is an insulated concrete form for tilt up construction. This system consists of expanded polystyrene panels and 18-guage steel attachment rails. These concrete form panels provide a lighter, faster, more energy efficient casting bed for all kinds of site-cast, tilt-up concrete walls.

Tilt Up Martin Concrete

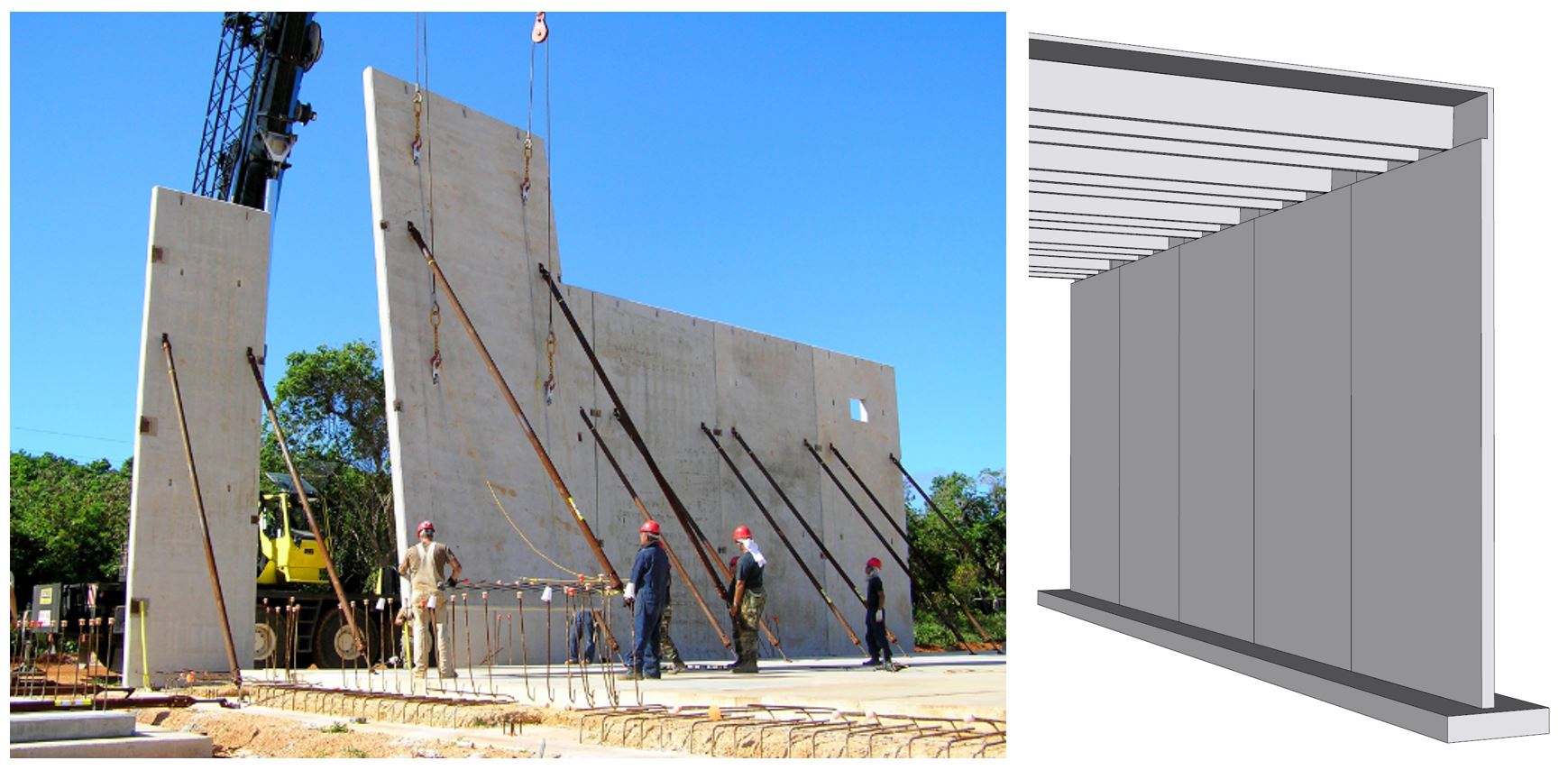

The process of constructing tilt up concrete wall structures involves several key steps: Concrete Wall Panel Casting: The construction team pours concrete into large forms or molds on the ground, creating wall panels. These panels are typically cast with reinforcing steel bars for added strength.

spWall TiltUp Wall Panels

Tilt-wall or tilt-up has become the construction method of choice for many commercial and industrial buildings, modern warehouses, call centers, distribution centers, retail stores, office and storage buildings and other types of facilities.. The idea behind tilt-up construction is a simple one. The concrete walls are formed horizontally on.

Concrete Tilt Up Panel Construction Tilt Constructions QLD

It's always less costly to do it right the first time. Always prepare tilt-up concrete surfaces thoroughly, removing all mold release agent residue. Be sure to prime the concrete surface with a high-quality acrylic masonry primer or sealer. Finally, be sure to use a 100% high-quality acrylic masonry paint for a durable, colorfast surface.

tilt up concrete panel tilt up concrete panel details Brilnt

Tilt-up concrete gets its name from the manner in which construction occurs: by lifting or tilting panels with a crane to form the walls of buildings. Panels can be produced in many shapes and sizes, including flat and curved sections. Concrete placement is fast and easy because it is done on the ground.

Precast Concrete, Tiltup Construction and Tiltwall What's the Difference in These Terms? Tiltup

Concrete tilt-up construction is a method of building with precast concrete wall panels that are erected directly onto the slab or foundation. This efficient technique is mainly used in commercial and industrial applications, as it requires fewer steps, therefore becoming more labor efficient than other construction methods..

The TiltUp Construction Process Explained Tiltwall Ontario Inc.

Tilt-up, in its most basic form, is a two-step process. First, slabs of concrete, which most often comprise load-bearing sections of a building envelope or elevation, are cast horizontally on a concrete slab-on-ground. The slabs, referred to as panels, are then lifted (tilted) with a crane after the concrete has reached sufficient strength.

How Do Tiltup Walls Work? Engineering Feed

form of tilt-up construction in which a tilting platform was used. Robert Aiken, in Monolithic Concrete Wall Building— Methods, Construction and Cost (Aiken 1909) , described the innovative method where walls for the building were constructed on a structural platform, then rotated or tilted upward by means of specially designed mechanical jacks,

The basics of TiltUp construction The Korte Company

Tilt-Up Construction: The Process of Erecting a Tilt-Up Building Explained Tilt Wall Ontario Inc. 545 subscribers Subscribe Subscribed 606 111K views 3 years ago #precast #concrete.

The TiltUp Construction Process Explained Tiltwall Ontario Inc.

38. ACI defines tilt-up as "a construction technique for casting concrete elements in a horizontal position at the job site and then tilting them to their final position in a structure.". ACI 318 further states that tilt-up concrete construction is a form of precast concrete. Several features make the tilt-up construction method unique.

554th RHS adapts durable, cost effective tiltup construction technique > Andersen Air Force

About the Tilt-Up Concrete Association. Founded in 1986, the Tilt-Up Concrete Association (TCA) strives to improve the quality and acceptance of site-cast Tilt-Up construction - one of the fastest growing industries in the United States, combining the advantages of reasonable cost with low maintenance, durability, speed of construction and minimal capital investment.

What is Tiltup Construction? How Are Tiltup Concrete Buildings Constructed? Tiltup

Tilt-up structures also offer all the energy efficiency, strength, and durability long associated with concrete. Sustainability Tilt-up is widely recognized as an environmentally friendly construction method. Because walls are cast on-site, transportation costs are minimized. Typically, the thermal mass of tilt-up eliminates the need for.

5 Benefits of Tiltwall Construction Canadian Concrete Expo

The Tilt-Up Concrete Association (TCA) describes tilt-up (also known as tiltwall) construction as follows: What is tilt-up? Tilt-Up construction is a method of building developed in the early 1900s where walls or building elements are cast on-site, typically on the floor slab of a building.

Tilt wall building

Tilt-up is a method of construction whereby large concrete panels are cast onsite and then raised into position with a crane. The building system, which was conceptualized in the early 1900s, is used throughout North America and across the globe. It is employed on virtually every building type, from distribution centers, to schools, churches.

What is a tilt up construction? Construction Company Ghana

Read customer reviews & find best sellers. Great prices & huge selections